| Model | Traditional pneumatic transportation | High performance air supply system |

| Conveying height | <40m | The current case is 65m (Yunyang, Chongqing) |

| Temperature and air pressure inside the conveying pipe | High (temperature>60, air pressure>700Kpa) | Low |

| Requirements for conveying pipelines | Special steel seamless pipe, replacement every 1-2 years | 10mm thick ordinary spiral plate, replaced every 5-6 years |

| Blockage phenomenon | Frequent occurrence and large amount of loose pipeline engineering | No occurrence, the pipeline can be buried underground |

| Energy consumption | Tall | Low (1/6 of traditional pneumatic transportation energy consumption) |

| Operating cost | Tall | Low (1/5 of the operating cost of traditional pneumatic transportation) |

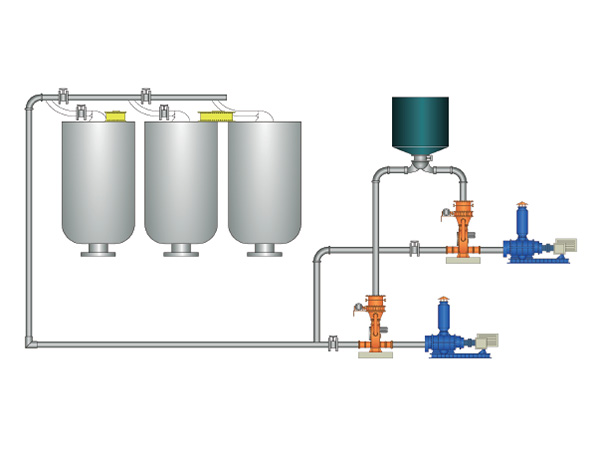

Warehouse to warehouse air delivery system |

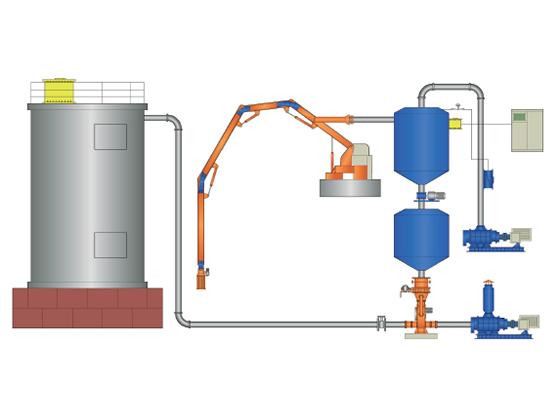

Positive pressure+negative pressure air supply system |

|

Chongqing Yunyang Hongqi Cement Factory Pier This project is used to coordinate with the spiral unloader to transport cement from the ship to the designated warehouse. Geographical situation on site: Annual drop in water level: about 32 meters Equipment installed capacity: Roots blower power: 280KW Conveying distance: horizontal distance of 242 meters+vertical height of 65 meters Conveying capacity: 90-100t/h Operation date: November 2015 When the area is in the dry season (with the lowest water level in the river), currently only our equipment can transport it. Therefore, during this period, the user raised the cement price by 20 yuan/ton. |

|

|

Chongqing Yunyang Hongqi Cement Factory Pier This project is used to coordinate with the spiral unloader to transport cement from the ship to the designated warehouse. Equipment installed capacity: positive pressure+negative pressure air supply motor power=160KW+250KW=410KW Conveying distance: Horizontal distance 192 meters, vertical height 32 meters Conveying capacity: 90-100t/h Operation date: August 2017 |